2 Chapter 2-Types of Thickeners and Their Functions

Learning Objectives

- Types of Thickeners and Their Functions

Two main types of starch thickeners are most popular in the bake shop.

- Cereal Starches- extracted from the endosperm of cereals such as wheat, rice, and corn. C

- Ex. Cornstarch and Flour

- Root Starches- extracted from various root or tuber plants

- Ex. Arrowroot and Tapioca

Cornstarch: the most commonly used starch in cooking and baking. It has almost twice the thickening power of flour. It cooks a nicely thickened and almost clear filling, though it weeps when frozen and then defrosted.

Flour: needs to be cooked with a fat (roux) to eliminate the pasty mouthfeel.

Arrowroot: is a bit expensive, but has a very clear finish. It doesn’t break down (weep liquid) when the product is frozen. It is often used in frozen food sauces because of its freezability.

Tapioca: comes from the cassava/yuca plant and is used in much the same way as cornstarch. If tapioca is used in its unprocessed form, it often results in a stringy texture. A better choice is tapioca pearls, which are modified to reduce stringiness.

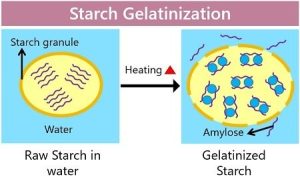

The Process of Starch Gelatinization: Don’t let the title fool you, starches and gelatin are two very different products, however, the process of starch molecules going from a dry powder to a thickened product is called “gelatinization”.

Here are the steps:

- Starch molecules start tightly packed in an orderly fashion inside a starch granule.

- When starch granules are placed in water, the molecules attract water and slightly swell.

- If the water is heated, the starch granules go through the irreversible process of gelatinization.

- When gelatinization occurs, the orderly starch molecules are disrupted by the water and become surrounded by moisture.

- The water is trapped by the molecules and the granules are swollen and all pushed up against one another. Therefore nothing moves freely and the product is thickened.

- If too much heat is applied to the product, the starch granules burst, releasing the molecules and water. At that point, your product is no longer thick, but often curdled and soupy.

This diagram shows the process of starch gelatinization:

(N, Supriya, 2024)

flour blended with and cooked in melted butter.